Kerawa Molds na baya da ƙirar samfura Kyauta

Sabis ɗinmu na Injection Molding

Amfani da Injin CNC don Isar da Babban Sakamako

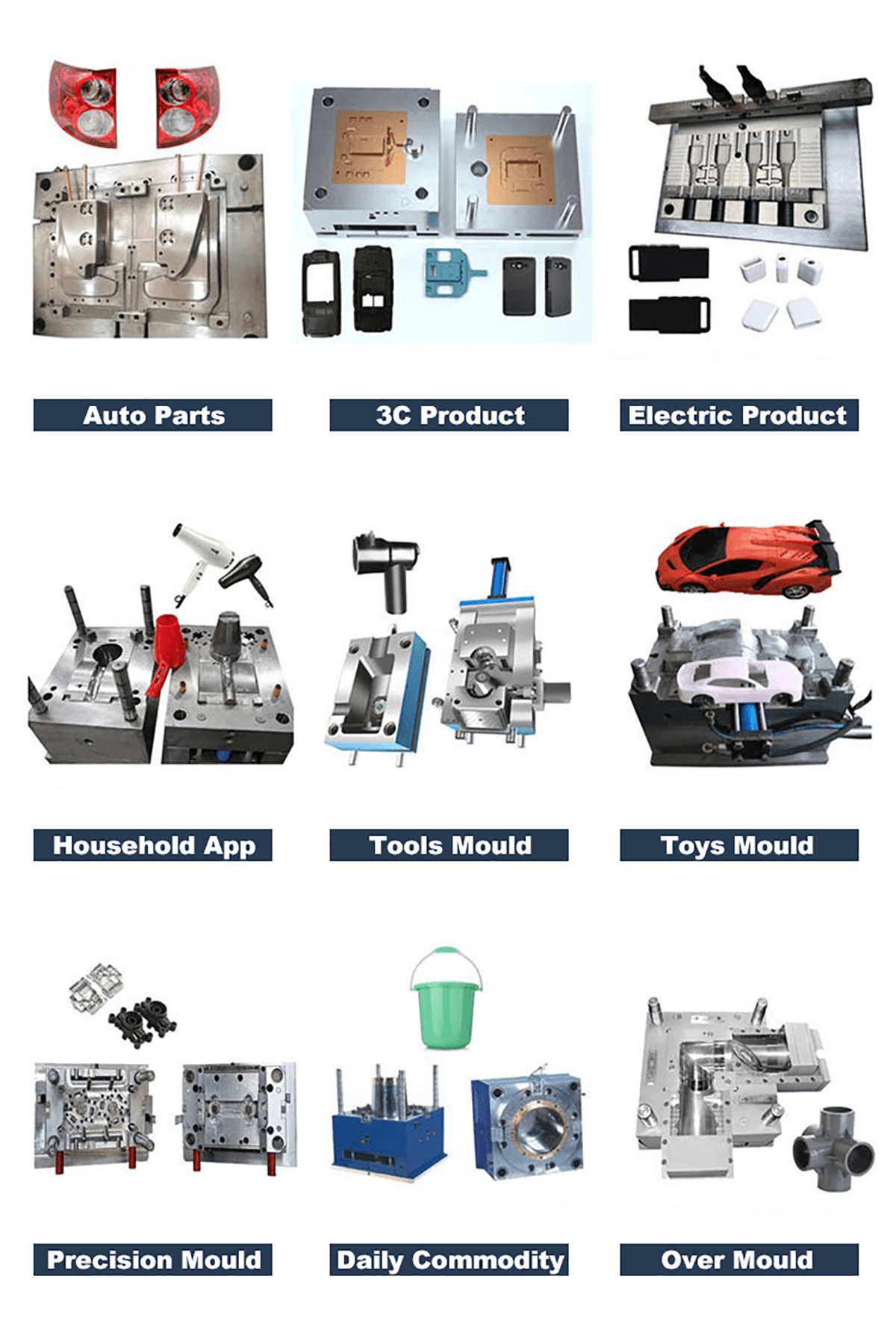

A fannin masana'antu, tsarin masana'anta na allurar filastik yana taka muhimmiyar rawa.Wadannan gyare-gyaren suna da mahimmanci don samar da samfurori daban-daban, ciki har da kayan gida, kayan wasan yara, kayan lantarki na 3C, kayan mota da kayan yau da kullum, da dai sauransu. A cikin kamfaninmu, muna alfahari da samar da sabis na gyare-gyaren filastik na farko.Tare da ƙwarewarmu na baya da ƙwarewarmu, mun ƙware da fasaha na masana'antun masana'antu zuwa mafi girman matsayin masana'antu.Bugu da kari, muna amfani da injina na CNC, sabon tsarin masana'antu wanda ke ba da tabbacin samar da sassa na allura cikin sauri da daidaito.

Game da mu:

Kamfaninmu yana da rikodin waƙa mai ban sha'awa a fagen samar da ƙura.Tare da shekaru na ƙwarewar masana'antu, mun sami nasarar sarrafa nau'ikan nau'ikan ƙira don saduwa da bukatun masana'antu daban-daban.Daga kayan aikin gida zuwa na'urorin lantarki masu yanke, muna haɓaka samfura da yawa don tabbatar da gamsuwar abokin ciniki kowane lokaci.Ƙoƙarinmu na ƙwarewa da kulawa ga daki-daki ya tabbatar da sunanmu a matsayin amintaccen mai ba da kayan allura na filastik.

Koyi game da allura molds:

Filastik gyare-gyaren gyare-gyaren tsari ne da ake amfani da shi sosai wanda ya haɗa da allurar narkakkar filastik cikin gyare-gyare na al'ada.Wannan tsari na iya haifar da hadaddun sifofi da sifofi waɗanda in ba haka ba zai yi wuya a cimma su.Abun filastik yana ƙarfafawa a cikin ƙirar, yana ɗaukar siffar da ƙira na rami.Da zarar an sanyaya kuma ya taurare, ana fitar da sassan da aka ƙera, a shirye don ƙarin sarrafawa ko haɗuwa.

Injection mold CNC machining:

A cikin kamfaninmu, mun sanya CNC machining wani muhimmin sashi na tsarin masana'antar mu.CNC (Computer Number Control) machining wata dabara ce da ke amfani da tsarin sarrafa kwamfuta don sarrafa injuna daidai.A cikin filin allurar filastik, injin CNC yana inganta inganci da daidaito, yana haifar da samfuran inganci.

Akwai fa'idodi da yawa don amfani da mashin ɗin CNC a cikin samar da allurar filastik.Na farko, yana rage girman lokacin samarwa da ake buƙata don kowane ƙira.Tsarukan sarrafa kwamfuta suna ba da damar yin aiki da sauri, madaidaicin mashin don kammala aikin cikin sauri.Rage lokutan gubar babban fa'ida ne ga kasuwanci kamar yadda ake fassara kai tsaye zuwa gajartar da zagayowar samarwa da sauri-zuwa kasuwa.

Na biyu, CNC machining yana tabbatar da daidaito na musamman a cikin samar da ƙwayoyin allurar filastik.Tsarin sarrafawa na atomatik yana da ikon ƙirƙirar ƙira mai sarƙaƙƙiya tare da madaidaicin madaidaicin.Wannan matakin madaidaicin yana tabbatar da cewa samfurin ƙarshe da aminci yana kwafin ƙirar da aka yi niyya, saduwa da takamaiman ƙayyadaddun bayanai da buƙatun abokin ciniki.

Bugu da ƙari, CNC machining yana ba da damar maimaitawa a cikin samar da ƙwayoyin allurar filastik.Tsarin sarrafa kwamfuta yana tabbatar da cewa kowane ƙirar da aka samar shine ainihin kwafin ainihin ƙira.Wannan daidaito yana da mahimmanci, musamman lokacin kera samfura a sikeli ko kiyaye daidaito tsakanin nau'ikan samfuri daban-daban.

a ƙarshe:

Kamfaninmu yana alfahari da samar da cikakkiyar sabis don ƙirar allura.Muna da tabbataccen tarihin samar da ƙwararrun ƙira don fagage daban-daban kamar kayan gida, kayan wasan yara, kayan lantarki na 3C, sassan mota da abubuwan yau da kullun.Amfani da mu na CNC machining yana ƙara haɓaka ikon mu na samar da kyawon tsayuwa cikin sauri da daidai.Wannan tsari na musamman na masana'antu yana tabbatar da cewa abokan cinikinmu da sauri suna karɓar kwafi na sassan filastik da suke buƙata.Ko kuna buƙatar gyare-gyare masu sauƙi ko ƙira masu sarƙaƙƙiya, za mu iya samar da mafita mai sauri da gamsarwa ga buƙatun ku na allurar filastik.

Cikakken Bayani

| Wurin Asalin | China |

| Sunan Alama | HSLD / Musamman |

| Yanayin Siffatawa | Fans Plastic Allurar Mold |

| Kayan aiki | CNC, EDM Yankan Injin, Injin Filastik, da dai sauransu |

| Kayan samfur | Karfe: AP20/718/738/NAK80/S136 Filastik: ABS/PP/PS/PE/PVC/PA6/PA66/POM |

| Mold Life | 300000 ~ 500000 Shots |

| Mai gudu | Mai Gudu Mai zafi ko Mai Sanyi |

| Nau'in kofa | Gefe/Pin point/Sub/Kofar Gefe |

| Maganin saman | Matte, Goge, Mirror goge, rubutu, zanen, da dai sauransu. |

| Kogon Motsi | Kogo Guda ɗaya ko Ƙaruwa |

| Hakuri | 0.01mm - 0.02mm |

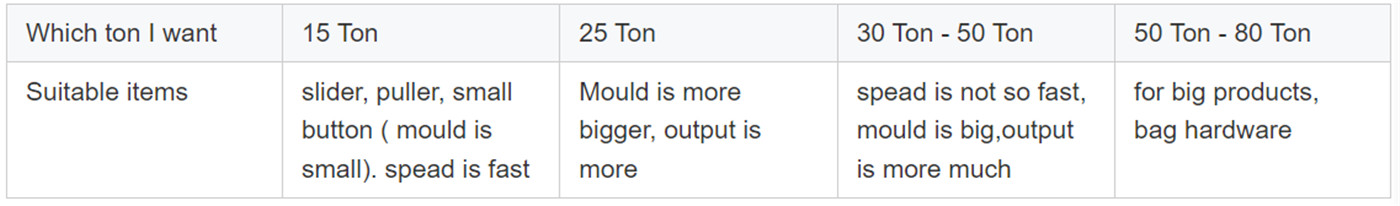

| Injin allura | Saukewa: 80T-1200T |

| Hakuri | ± 0.01mm |

| Samfurin kyauta | samuwa |

| Amfani | mafita tasha ɗaya / ƙira kyauta |

| Filin aikace-aikace | Kayan lantarki, kayan kwalliya, samfuran likitanci, samfuran gida da aka yi amfani da su, samfuran motoci, da sauransu |

Cikakkun masana'antu

Ƙarin Molds

Jirgin ruwa

Sabis na marufi na musamman a gare ku: Cakulan katako tare da fim

1. Don mafi kyawun tabbatar da amincin kayan ku, ƙwararru.

2. Kyakkyawan yanayi, za a ba da sabis na marufi masu dacewa da inganci.

FAQ

HSLD: Ee, yawanci kayan gyara don simintin gyare-gyaren mutuwa muna da abin saka mold, firam ɗin ƙira, ainihin taga, cibiya mai motsi, shugaban bututun ƙarfe.Kuna iya bincika kuma ku sanar da abubuwan da kuke buƙata.

HSLD: Abubuwan da muke sakawa an yi su da DAC.

HSLD: Cibiyoyin motsinmu an yi su ne daga FDAC.

HSLD: iya.

HSLD: Kayan aiki daban-daban suna da daidaito daban-daban, gabaɗaya tsakanin 0.01-0.02mm